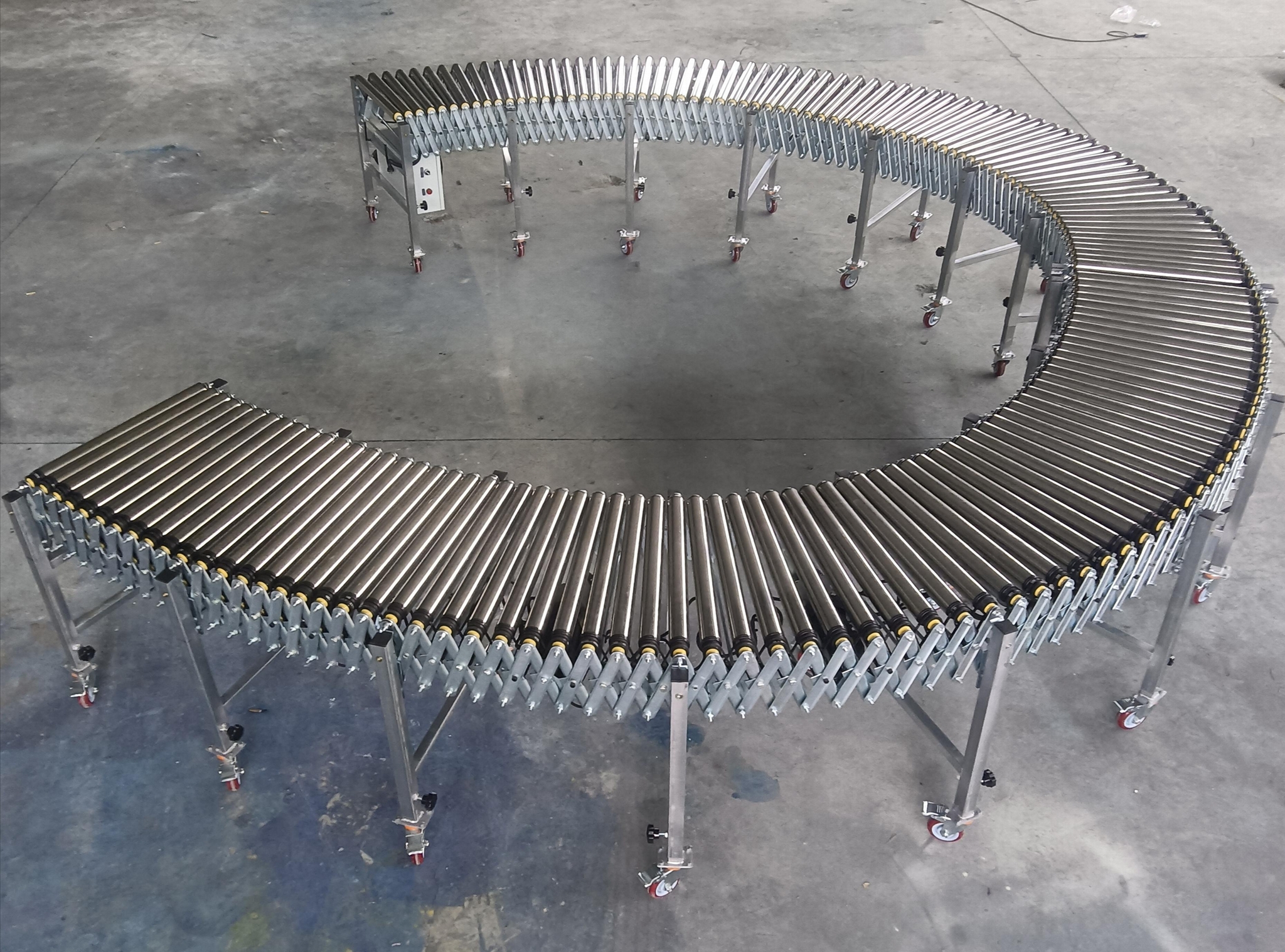

Telescopic roller conveyor

Model No.︰-

Brand Name︰letuxing

Country of Origin︰China

Unit Price︰US $ 133 / pc

Minimum Order︰1 pc

Product Description

Structural composition

Drum: It is the main part of the conveyor line, which is composed of a series of continuous drums, which are used to carry and transport goods, and the materials are usually carbon steel galvanized, stainless steel, aluminum alloy, lagging rubber, etc.

Telescopic mechanism: It is the core part, and there are two common types: chain type and connecting rod type, which are used to adjust the length of the conveyor line.

Drive device: used to drive the drum to rotate, can be located at the beginning and end of the conveyor line or distributed on the whole conveyor line, and the power mode is geared motor drive, electric drum drive, etc.

Control system: used to control the start, stop, speed and other parameters of the conveyor line, the common ones are electrical control system and pneumatic control system.

Accessories: such as brackets, rails, guard plates, etc., which can increase the stability and safety of the equipment.

Working principle: When the length of the conveyor needs to be adjusted, the control system receives the signal and starts the telescopic mechanism to make it expand or contract to change the length of the drum. After that, the power source drives the drum to rotate, and the material placed on the drum is transferred along the conveyor line to the target position.

Performance characteristics:

Flexible: small footprint, flexible and retractable, up to 3 times the ratio of the longest to shortest unit, variable direction, up to 180 degrees of steering.

Easy to move: The caster device is easy to move, and the lifting device can be flexibly adjusted to the unit or overall height, and can also be adjusted to an inclined surface.

Strong conveying capacity: the conveying carrier is diverse, which can be rollers or rollers, with electric rollers or micro motor drives, which is more convenient and labor-saving, and has a strong load-bearing capacity.

Fields of application

Logistics and warehousing: In logistics centers and warehouses, it is used to sort and transport parcels, goods, and pallets, and the length can be adjusted according to the flow of goods and the layout of storage.

Production line: In automobile manufacturing, electronic equipment production and other production lines, parts or finished products can be transferred from one workstation to another to improve production efficiency.

Wharf: It is used for unloading and loading operations at the wharf, which can adapt to the loading and unloading needs of cargo ships and goods of different sizes and types.

Food Processing and Packaging: Used to convey food products and ensure the quality and safety of food during processing and packaging.

Product Image